Aquio explains food grade shipping containers and the challenges it presents to shipping lines.

A food grade shipping container is a container that has met the strict requirements of being able to transport food and plant products intended for human consumption without tainting or damaging the cargo.

What are the challenges food grade shipping containers present?

Given the costs associated, outlined by Shipping Australia, with upgrading a general cargo shipping container to food quality, shipping lines have been hesitant in having too many available as the cost of upgrading is not recouped when using it for general cargo. As food is such an integral part of global supply chains, shipping lines are wanting to meet the various seasonal demands.

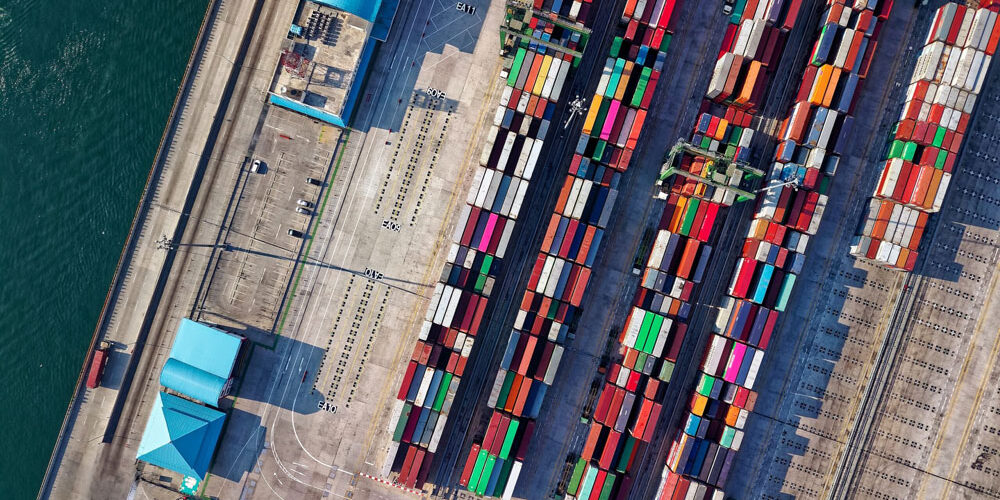

In Australia, we suffer from an imbalance of importing general cargo and exporting food cargo that results in an excess of general cargo shipping containers unfit for transportation of food.

What is being done to change this?

Common methods that have been used to upgrade general cargo containers to food quality usually involve water washing with cleaning agents. During cooler and winter months the weather conditions are not favourable for quick drying of the container and can result in delays in the supply of food quality containers. Waiting to release a container before it is fully dried after a water wash can result in tainting a food cargo as well as bacterial growth and mould.

Another limitation of water washing to clean containers is that it requires open-door ventilation and containers are unable to be stacked with open doors as this takes up precious space in empty container parks, making it harder to continue operations as usual.

How is Aquio solving this problem?

Our floor coating product, NutriSkin™, is applied by paint roller allowing upgrades to be conducted in virtually any location in the world with no capital investment in application equipment. Furthermore, a roller application results in lower emissions during application as no carbon fuels are required to power equipment.

These products have been designed as a single coat application, which requires less time (10 – 15 minutes) than solvent-based products (usually up to 3 coats and curing time and up to 3 hours for complete application). The products can be coated over existing transferable stains, even when wet; and once cured, will prevent those stains and odours from tainting the cargo. Generally, just a sweep out and removal of loose particles and debris is required prior to application. (See the NutriSkin application process)